If you want to attract the best transport and logistics job candidates, make sure the job description contains all the duties. These duties can range from ordering raw materials to filling company paperwork. This can make the job description more appealing but it could also lead to the hiring of the wrong person. This can lead to problems for customers and businesses. You will also need to invest time and money in training the new employee.

Job description

The logistics and transport professions work in many different industries, moving people and goods from A to B. Some professionals work in shipping. Others may be involved with road maintenance. The work involves monitoring the safety of products and monitoring traffic congestion. Those who work in this field are often required to adapt to changing business needs and work in various locations.

A job description should be focused on the necessary skills and training for a job and reflect the company's culture. The job description should include information about whether the position is permanent, temporary or self-employed.

Salary

Opportunities for transportation and logistics jobs are numerous, with entry-level positions up to more senior ones. Salary levels will vary depending on industry and your level of experience. The average salary for entry-level positions is $40,000 annually. There is still room for advancement, though, as these salaries can increase.

Transportation and logistics careers have a variety of salary options, and some are more lucrative than others. Although entry-level salaries might be lower than other fields, experienced workers can earn significantly more. Some companies offer in house training, or even pay for graduate education.

Requirements

Transportation and logistics jobs are highly valued in many industries and require a high level of competence. The primary goal of these jobs is to ensure that goods are delivered on time and at the lowest cost. Companies must ensure that they hire the right people with the right skills. While junior staff may not need any prior training, those wishing to take up a senior position should have relevant qualifications, such as a Supply Chain Practitioner Advanced Apprenticeship, or Chartered Institute of Logistics and Transport accredited certifications.

Good grades are the first step in your journey to a career working in logistics and transport. You can take many courses to increase your skills and knowledge. The Chartered Institute of Logistics and Transport (CILT) UK offers a Level 2 Certificate in Transport and Logistics, which is ideal for new entrants to the field. Many logistics companies offer graduate recruitment programs that can help you gain valuable work experience.

Localities

The career opportunities in logistics and transport are varied. They often involve planning and assessing different methods of distribution. These jobs also require a high degree of analytical thinking and the ability to manage complex data. Excellent communication skills are essential. Some jobs will require you to travel to remote locations. Graduate training programmes in logistics and transport are available. They provide you with the skills required to succeed in this field. Some of these programmes will also provide you with paid internships.

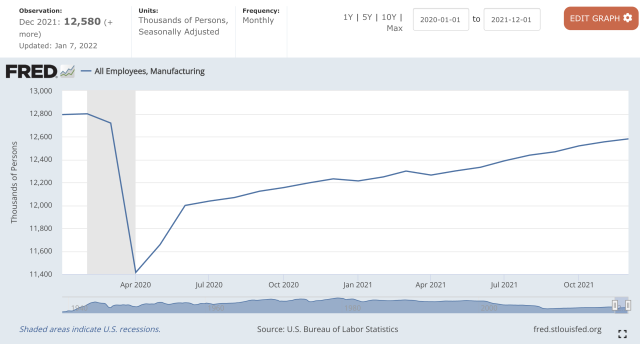

High demand occupations in logistics and transportation are expected increase by 3% between 2019-2029, similar to the national average. However, some occupations are expected to grow faster than average such as those that require commercial pilots or airline pilots. Other occupations in this sector include drivers/sales people and delivery truck driver.

FAQ

What is the responsibility of a logistics manager?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is accomplished by using the experience and knowledge gained from working with company products. He/she must also ensure sufficient stock to meet the demand.

How can manufacturing efficiency improved?

First, determine which factors have the greatest impact on production time. Then we need to find ways to improve these factors. You can start by identifying the most important factors that impact production time. Once you've identified them all, find solutions to each one.

How does manufacturing avoid bottlenecks in production?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning for capacity requirements as well as quality control measures.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It's all about eliminating variation and creating consistency in work.

Why is logistics so important in manufacturing?

Logistics are an essential component of any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

What does it take for a logistics enterprise to succeed?

To run a successful logistics company, you need a lot knowledge and skills. To communicate effectively with clients and suppliers, you must be able to communicate well. It is important to be able to analyse data and draw conclusions. You need to be able work under pressure and manage stressful situations. To increase efficiency and creativity, you need to be creative. You must be a strong leader to motivate others and direct them to achieve organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

What's the difference between Production Planning & Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. This is accomplished by forecasting the demand and identifying production resources.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

What is the role and responsibility of a Production Planner?

Production planners ensure all aspects of the project are delivered within time and budget. They also ensure that the product/service meets the client’s needs.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If it is too large, it means that there are problems.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have this understanding, you will need to identify sources and causes of variation. It is important to identify whether the variations are random or systemic. Random variations happen when people make errors; systematic variations are caused externally. You could consider random variations if some widgets fall off the assembly lines. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. The solution could involve changing how you do things, or redesigning your entire process. To verify that the changes have worked, you need to test them again. If they don’t work, you’ll need to go back and rework the plan.