Manufacturing associations offer members the opportunity to share resources and information, and network. Businesses can gain from this in many ways. Members can also use it to make sure that their concerns about manufacturing reach government officials on all levels.

The Manufacturing Institute

The Manufacturing Institute is a nonprofit organization that aims to promote and encourage the advancement of manufacturing. It does this through the use of technology, education and training. It also promotes the value of manufacturing, by recognizing people in the field as well as the importance to the entire society.

American Manufacturers Association

The American Manufacturers Association is a trade association that focuses on helping companies develop and use the latest technologies in order to improve their business strategies. Members can also get legal advice or updates on manufacturing news.

NAM is the National Association of Manufacturers

The National Association of Manufacturers is a 501(c)(6) trade association that represents small and large manufacturers across the country. Its main goal is to get the government to implement policies that will benefit manufacturers and their workforce.

NAM belongs to the Council of Manufacturing Associations. It is an association of 260 associations which work together to address issues affecting the manufacturing industry. It is also a World Trade Organization member and works to lower trade obstacles.

Fabricators and Manufacturers Association of International

The Fabricators & Manufacturers Association, International is a trade association that focuses on the metal processing, forming and fabricating industries. The organization's main goals are to promote and grow the industry as well as encourage young minds into the manufacturing sector by offering scholarship programs.

FMA also focuses on training and networking, as well as encouraging the industry to grow its workforce through a variety of initiatives. They offer certifications, conferences and seminars for their members, as well as an apprenticeship program.

ISO

ISO is one of the most important standards bodies in the world. Its main purpose is to create technical standards for businesses that will help them maintain high levels of quality. The ISO does this by using voluntary consensus standards which ensure consistency in the quality of products.

ANSI

The American National Standards Institute, a trade group that aids businesses in product quality, is an association. Its objectives include reducing the likelihood of product defects and increasing production efficiency.

SME

SME is a non-profit organization that focuses primarily on the development of the manufacturing industries. This is done through technology, education and research. It also tries to promote the value and benefits of manufacturing by recognizing the people who work within it and the importance of it to society as compared to other jobs.

MHI

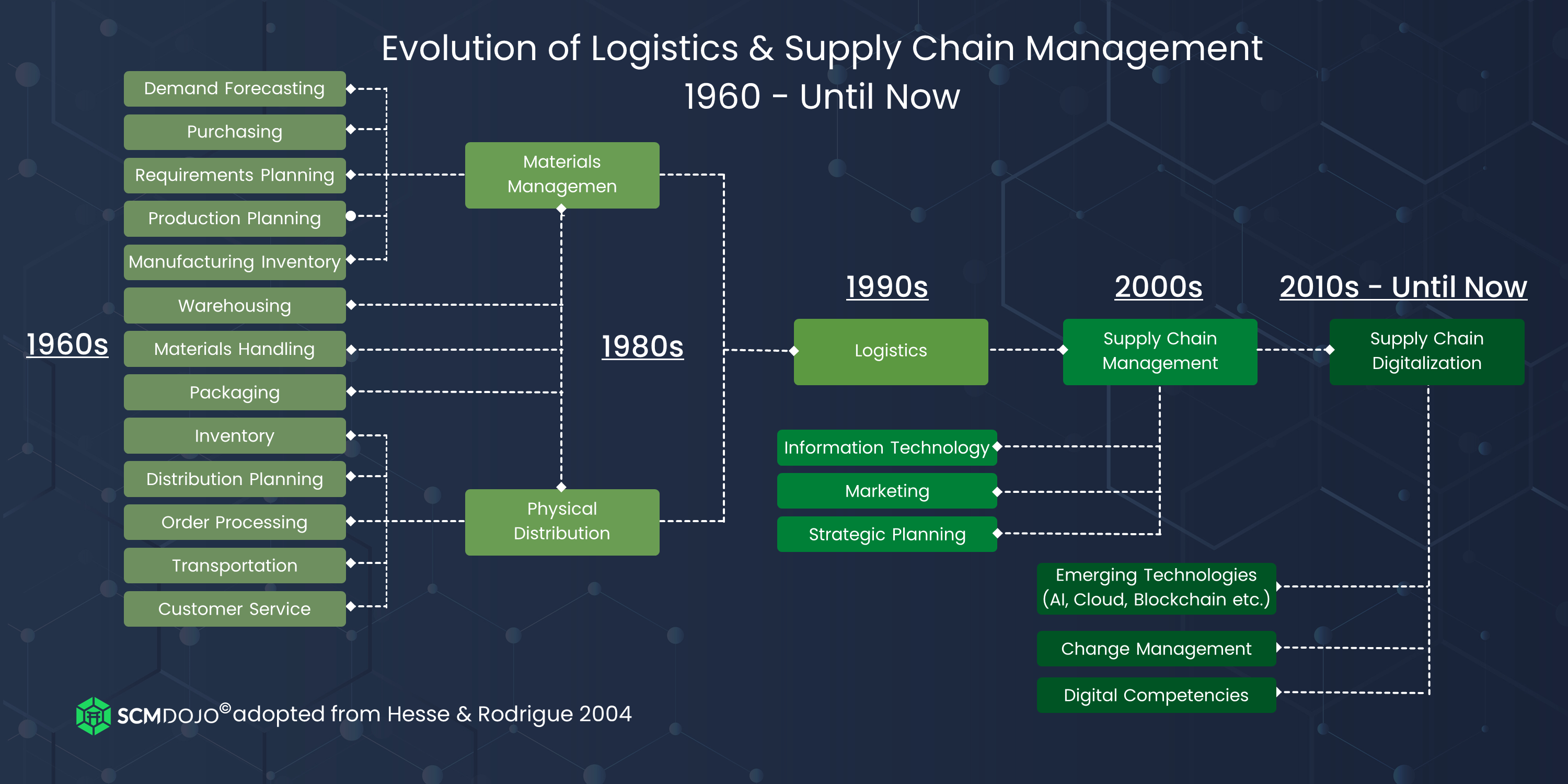

MHI, a trade organization that focuses primarily on supply chain management, logistics and material handling is the MHI. The MHI's goals are to grow and sustain their industry, improve the health of its members and ensure that they have access quality products and services.

FAQ

What does the term manufacturing industries mean?

Manufacturing Industries is a group of businesses that produce goods for sale. The people who buy these products are called consumers. This is accomplished by using a variety of processes, including production, distribution and retailing. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What is the role of a logistics manager

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is accomplished by using the experience and knowledge gained from working with company products. He/she should make sure that enough stock is on hand to meet the demands.

What types of jobs can you find in logistics

There are many kinds of jobs available within logistics. Here are some:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers – These people oversee inventory at warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service representatives - Answer calls and email from customers.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

Are there ways to automate parts of manufacturing?

Yes! Since ancient times, automation has been in existence. The wheel was invented by the Egyptians thousands of years ago. To help us build assembly lines, we now have robots.

There are many uses of robotics today in manufacturing. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Automation can be applied to manufacturing in many other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

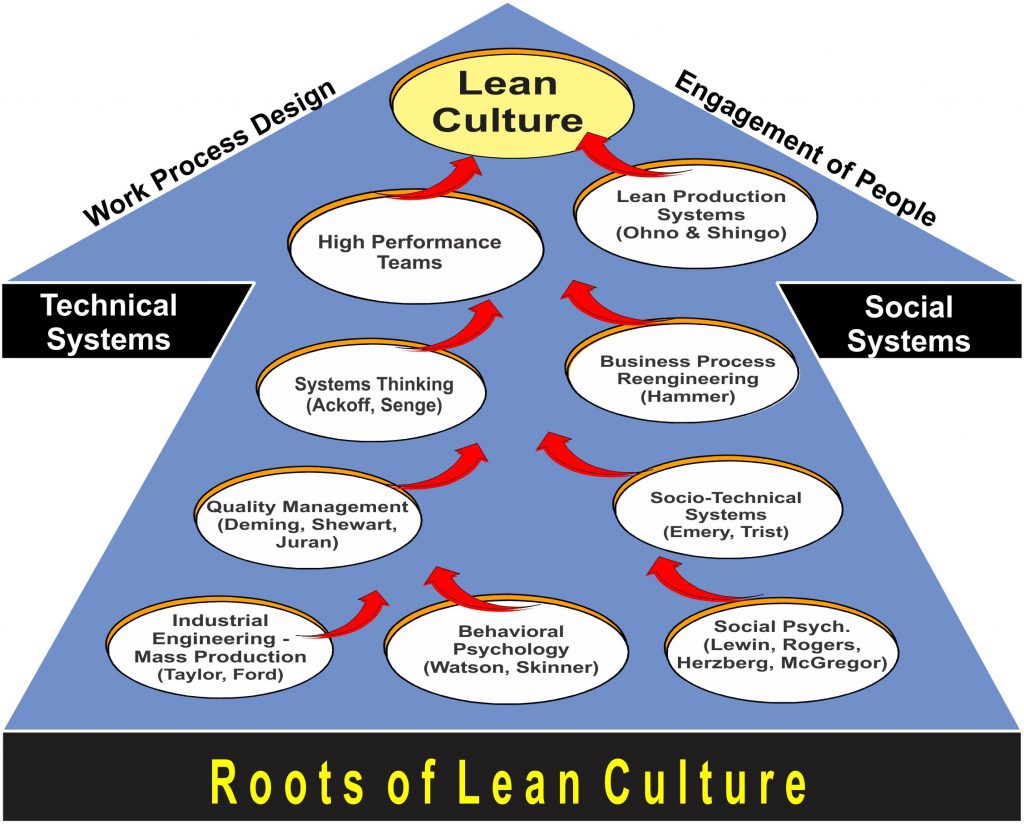

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Many industries worldwide use lean manufacturing. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Lean manufacturing includes five basic principles:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses have adopted lean production techniques to make them more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. You should repair any part that needs to be repaired during an assembly line. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. It involves continuous improvement of processes, people, and tools.