Effective supply chains can impact all aspects within a business. Customers will be satisfied, costs will drop and the company's growth will increase. The supply chain is a crucial factor for your business's success, regardless of its size.

The supply chain is often the most overlooked area of a business but one that has the biggest impact on your overall performance and ROI. You will experience fewer delays, and you'll spend less on material shortages when your supply chain runs smoothly.

Successful supply chain control also increases customer satisfaction through the delivery of the right product in the right quantity at the appropriate time. Additionally, it increases profitability and enhances the reputation of your company.

Since a very long time, businesses have sought to increase the speed of supply and reduce the costs. They have heavily invested in new technologies and infrastructure.

Numerous studies have revealed that the supply chain management abilities of a company have a profound impact on its performance, both financial and operationally. These factors determine the efficiency of a business and its ability to meet customer needs.

When supply chain managers are well trained and have a strong understanding of the end-to-end business, they are able to make the appropriate trade-offs that lead to cost savings. By working closely with all parties in the supply chain, they can improve customer satisfaction, increase profits and create better supplier relationships.

In a world where markets are moving quickly and product cycles are shorter, it is critical to be able adjust quickly. It involves analyzing and managing raw stock, transit times, as well as supplier lead-times in real time. The numbers need to be accurate, meaningful and granular.

Supply chain managers need to understand how a missed delivery can affect the bottom line. In addition, they must be able to plan for backup supplies.

These backups will help them overcome unforeseeable challenges. The flexible supply chains will give them a significant competitive advantage against their rivals.

The most important part of any successful business is a well-organized supply chain. This helps to ensure that the right products are delivered at the perfect time for consumers. This increases their loyalty and fulfills their needs.

In order to determine the best alignment of your supply chain to the manufacturing network and the distribution system, you must consider the different phases of a products' life cycle. This will help you to create optimal supply chain solutions that can meet the unique needs of each product type and stage in its lifespan.

A good supply chain strategy will ensure that it is a 'fit for purpose' organisation that can evolve from being agile and responsive, efficient and low-cost or innovation driven.

The organizational design of the Supply Chain function interacts and supports its business strategy through assets, technology, process, and people. When these elements don't match, execution can be difficult and a business' supply chain could fail to deliver.

FAQ

What is production planning?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document will ensure everything is in order and ready to go when you need it. You should also have information to ensure the best possible results on set. This includes location information, crew details, equipment specifications, and casting lists.

The first step is to decide what you want. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. Do you need people sitting in the front seats? You might also need someone to help you get around the back. You may want to change the interior's color from black or white. These questions can help you decide the right look for your car. It is also worth considering the types of shots that you wish to take. Do you want to film close-ups, or wider angles? Maybe you want the engine or the steering wheels to be shown. These details will help identify the exact car you wish to film.

Once you have made all the necessary decisions, you can start to create a schedule. You can create a schedule that will outline when you must start and finish your shoots. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. Everyone will know what they need and when. If you need to hire extra staff, you can make sure you book them in advance. There is no point in hiring someone who won't turn up because you didn't let him know.

Also, consider how many days you will be filming your schedule. Some projects may only take a couple of days, while others could last for weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Shooting multiple takes over the same location will increase costs and take longer to complete. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. It is important to set a realistic budget so you can work within your budget. If you have to reduce your budget due to unexpected circumstances, you can always lower it later. But, don't underestimate how much money you'll spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. This is done through forecasting demand and identifying production capacities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

What is it like to manage a logistics company?

To be a successful businessman in logistics, you will need many skills and knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. You must be able analyze data and draw out conclusions. You must be able to work well under pressure and handle stressful situations. To improve efficiency, you must be innovative and creative. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

You must be organized to meet tight deadlines.

Why automate your factory?

Modern warehousing has seen automation take center stage. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses must adapt quickly to meet changing customer needs. To do so, they must invest heavily in technology. Automating warehouses is a great way to save money. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety enhancements

-

Eliminates bottlenecks

-

Companies can scale more easily

-

Makes workers more efficient

-

This gives you visibility into what happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

Quality products delivered on time

-

Eliminates human error

-

Assure compliance with regulations

What is the importance of logistics in manufacturing?

Logistics are an integral part any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics play a key role in reducing expenses and increasing efficiency.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

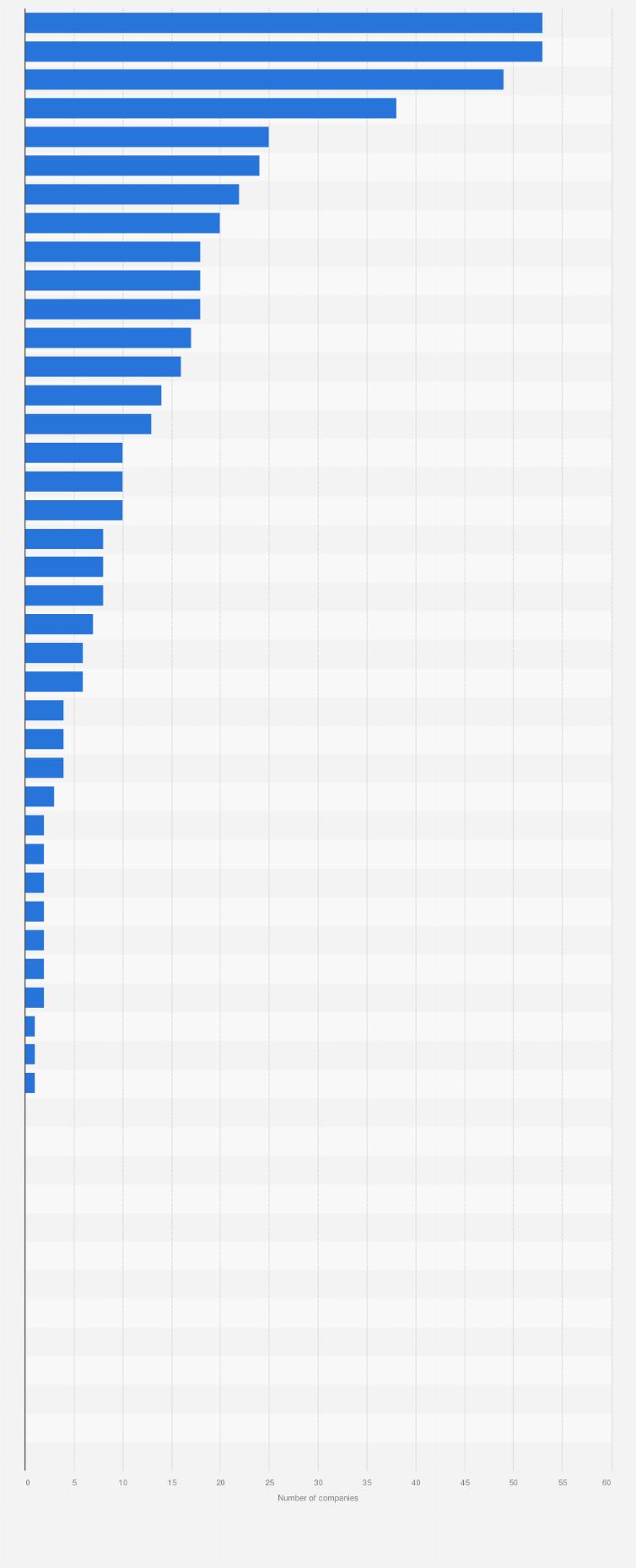

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use the Just In-Time Production Method

Just-in-time is a way to cut costs and increase efficiency in business processes. It is a process where you get the right amount of resources at the right moment when they are needed. This means that your only pay for the resources you actually use. Frederick Taylor developed the concept while working as foreman in early 1900s. He saw how overtime was paid to workers for work that was delayed. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are many JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow you to track how much material you have left over after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to predict how much you can expect to sell.

-

Project-driven: This means that you have enough money to pay for your project. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based: This is the most common form of JIT. You allocate resources based on the demand. For example, if there is a lot of work coming in, you will have more people assigned to them. You'll have fewer orders if you have fewer.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT: A variation on resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT is another variant of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT: One of the most recent forms of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, your goal is to add value to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It's the process of scheduling delivery of components immediately after they are ordered. It is essential because it reduces lead-times and increases throughput.