The Great Recession saw the manufacturing industry lose nearly 2 million jobs. Although some industry jobs have been reclaimed, the rate of job growth has remained slow. Manufacturing faces numerous headwinds including higher prices, tariffs and a fading effect of the 2017 tax cut for corporations. Slow global growth adds to these challenges.

The manufacturing industry is broad and diverse. These jobs include administrative, technical, production, and entertainment jobs. These jobs often require little to no hands-on labor. For example, manufacturing workers are responsible for the assembly and packaging of a variety of products for sale. They are responsible for monitoring production and transporting raw materials. In addition, there are jobs in science, technology, and math.

Not only are there jobs in traditional manufacturing, but advanced manufacturing is also available. These jobs are extremely technical and may be transferable to other industries. Advanced manufacturing employers may offer benefits and training opportunities, such as apprenticeships. They might also offer great wages. They can be difficult to find. A labor shortage could create incentives for employers to offer advanced manufacturing jobs.

The diversity of roles in the manufacturing industry is one of the best aspects. There are many roles for workers in the manufacturing industry, including power plants and bakeries. They may also manage a production team or perform administrative tasks. They may also be involved in food processing, such as fish cutters, meat cutters, and batchmakers.

Although there are many options for occupations in the manufacturing industry to choose from, the best ones are usually in managerial or professional roles. The minimum educational requirement for most production positions is a high school diploma. A bachelor's degree, however, is more preferred. It is also desirable to have a technical education, particularly for jobs in manufacturing, where many workers will need to operate plant machinery. In addition, jobs in the science and technology industries have seen recent growth.

You can showcase your skills in production jobs. If you are looking for a career in film, video, or animation, you might consider offering to work for free at a production company in exchange for references. This can provide valuable experience that can lead to rewarding connections. However, you should also research the production industry in your area to determine whether there is demand for your skills. Also, you should determine if your skills are sufficient to be considered for entry-level production jobs.

Multiple research studies have shown that the number of workers in temporary jobs has increased dramatically in the production sector. This is due to the Great Recession. The use of temporary workers in the construction and healthcare sectors has declined over the past five year, while the number of people working in the computer and mathematical fields has increased. However, the use of temporary workers in manufacturing has increased by almost twofold over that time.

The production industry also has a number of other interesting jobs, including audio engineers and sound technicians. A small increase has been seen in the number women working in manufacturing positions. Over the past year, the percentage women working in production has increased by 5.3%. The industry's women workers have not seen an increase in their numbers at the same time as men. This is due to the fact most people in the sector work as assistants.

FAQ

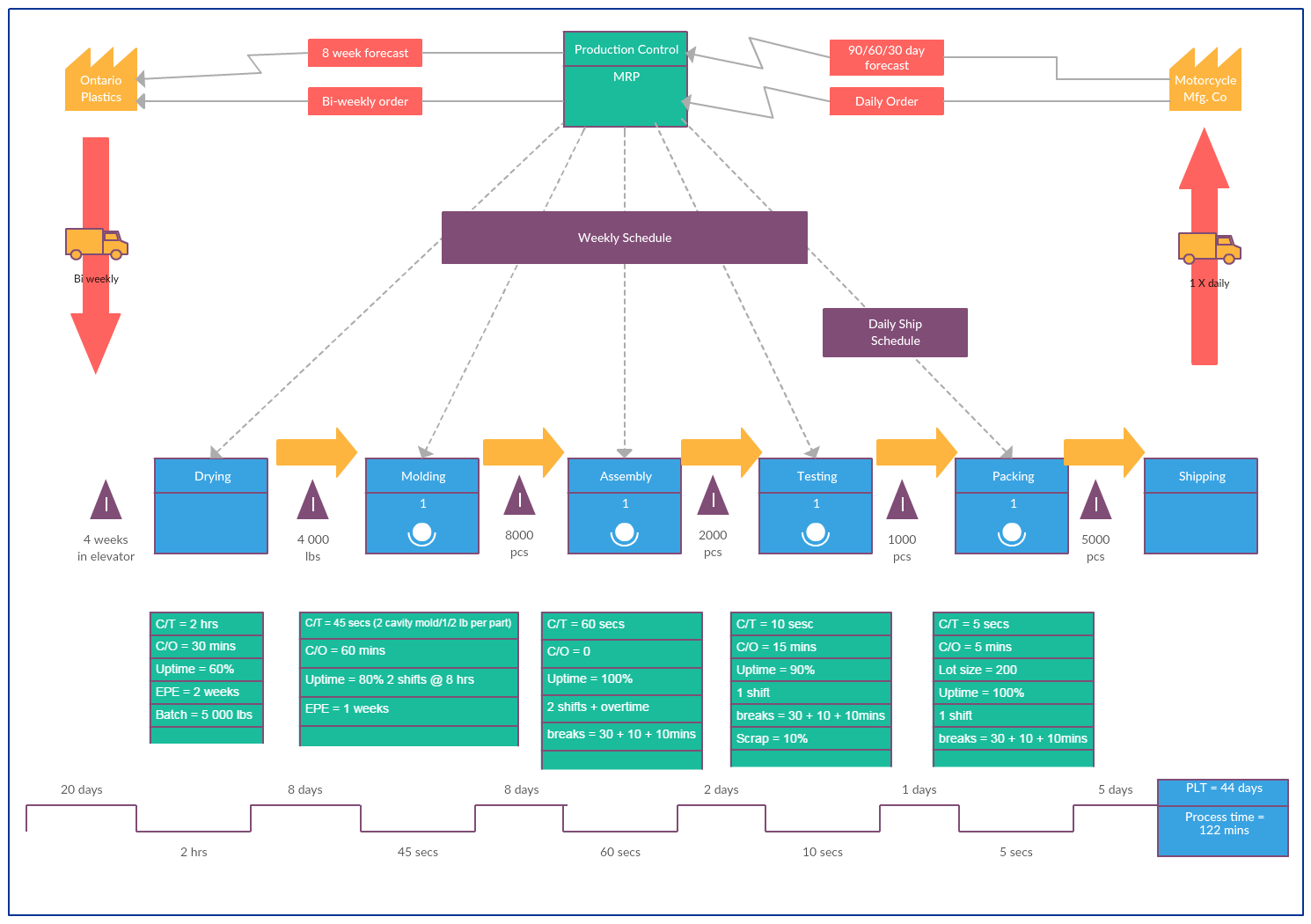

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. Forecasting demand is one way to do this.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

How can manufacturing excess production be decreased?

Improved inventory management is the key to reducing overproduction. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. We could use these resources to do other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban board is a visual display used to track work in progress. A Kanban system allows work items to move through several states before reaching their final destination. Each state represents a different priority level.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. If a task is still in its beginning stages, it will continue to be so until it reaches the end.

This allows work to move forward and ensures that no work is missed. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does not contribute to the product's value is considered waste. The following are examples of common waste types:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What does it take to run a logistics business?

A successful logistics business requires a lot more than just knowledge. You must have good communication skills to interact effectively with your clients and suppliers. You should be able analyse data and draw inferences. You must be able and able to handle stress situations and work under pressure. You must be creative and innovative to develop new ideas to improve efficiency. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

You must be organized to meet tight deadlines.

What are the 7 Rs of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The following letters make up the acronym:

-

Responsive - ensure all actions are legal and not harmful to others.

-

Reliable - Have confidence in your ability to fulfill all of your commitments.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful - Treat people fairly and equitably

-

Be resourceful: Look for opportunities to save money or increase productivity.

-

Recognizable - Provide value-added services to customers

What is the responsibility of a manufacturing manager?

The manufacturing manager should ensure that every manufacturing process is efficient and effective. They must also be alert to any potential problems and take appropriate action.

They should also know how to communicate with other departments such as sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

What does manufacturing industry mean?

Manufacturing Industries refers to businesses that manufacture products. These products are sold to consumers. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. These companies produce goods using raw materials and other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Can certain manufacturing steps be automated?

Yes! Yes. The Egyptians invented the wheel thousands of years ago. We now use robots to help us with assembly lines.

There are many uses of robotics today in manufacturing. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Automation could also be used to improve manufacturing. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation developed the 5S method in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

The idea behind standardizing production processes is to make them repeatable and measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps that you need to follow in order to implement 5S. Each step requires a different action, which increases efficiency. By sorting, for example, you make it easy to find the items later. When you arrange items, you place them together. Once you have separated your inventory into groups and organized them, you will store these groups in easily accessible containers. You can also label your containers to ensure everything is properly labeled.

Employees will need to be more critical about their work. Employees need to be able understand their motivations and discover alternative ways to do them. To be successful in the 5S system, employees will need to acquire new skills and techniques.

The 5S method increases efficiency and morale among employees. They feel more motivated to work towards achieving greater efficiency as they see the results.