Getting the best value for your money is critical when choosing a course for your business. This course will educate you about the importance of procurement and the role that procurement management plays in business. Here are a few of the factors that should play a part in your decision making process. Learn more about Cost-based pricing, Contracting and Negotiating to help you make the best deal for your business. Here are some things to look at when choosing a course supplier:

Cost-based pricing

Future Procurement teaches Cost-Based Pricing to production and purchasing professionals. It's designed to assist both beginners and more experienced Procurement Professionals in understanding and using Cost-Based pricing in their everyday work. It is available online and free to download. This makes it easy to get a basic understanding of CBP and how it applies to different types courses. CBP implementation in course procurement strategies is important.

Negotiating

A negotiation course is a great way to improve your negotiation skills. There are many courses available in negotiation, both online and in-classroom. The course helps you understand the fundamentals of how to communicate effectively and establish mutually beneficial relationships. This course can also help you get a job in the negotiation field. Read on for more information. Below are some tips for getting the most out this course.

Contracting

This workshop is beneficial for students interested in contracting careers. It will provide information about the different activities involved during the sourcing phase. Anyone involved in procurement, no matter how new or experienced, will find this workshop useful. Here are some of the objectives:

Partnering with other organizations

The course is taught in a facilitated classroom environment and includes six sessions that use case studies, workbooks, real-world experience procurement, and each uses workbooks. At the end of the course, participants will participate in a role-play exercise, gathering their learning and assessing their understanding of the training. Participants will gain an awareness of the various sales techniques and behavior. We will be discussing some of the advantages of this workshop and what to expect from it.

Certifications

The Certificate in Course Procurement, (CPP), will allow you to learn about the basics of supply chain management. You will also gain valuable knowledge about current trends and contemporary issues in the field. This course will boost your negotiation and outcome skills, giving you an edge over your competition. It is best to aim for a 2.5 average in grades and finish the program within three year. This course will also teach you about legal and regulatory considerations that affect the procurement process.

Course platforms

There are many course platforms that you can purchase. Each platform has its own strengths and weaknesses. Some offer premium social learning tools, high interactivity and superior quality. Others have a simpler interface with fewer features and offer a simpler interface. Teachable is still one of the most popular online courses platforms. If you want to create a course that is easily accessible to the public, however, you might consider looking elsewhere.

FAQ

What does the term manufacturing industries mean?

Manufacturing Industries are businesses that produce products for sale. The people who buy these products are called consumers. This is accomplished by using a variety of processes, including production, distribution and retailing. They make goods from raw materials with machines and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

What can I do to learn more about manufacturing?

You can learn the most about manufacturing by getting involved in it. You can also read educational videos or take classes if this isn't possible.

How can we improve manufacturing efficiency?

The first step is to identify the most important factors affecting production time. Next, we must find ways to improve those factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them all, find solutions to each one.

Is it possible to automate certain parts of manufacturing

Yes! Yes. Automation has been around since ancient time. The Egyptians invent the wheel thousands of year ago. We now use robots to help us with assembly lines.

There are many applications for robotics in manufacturing today. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation could also be used to improve manufacturing. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

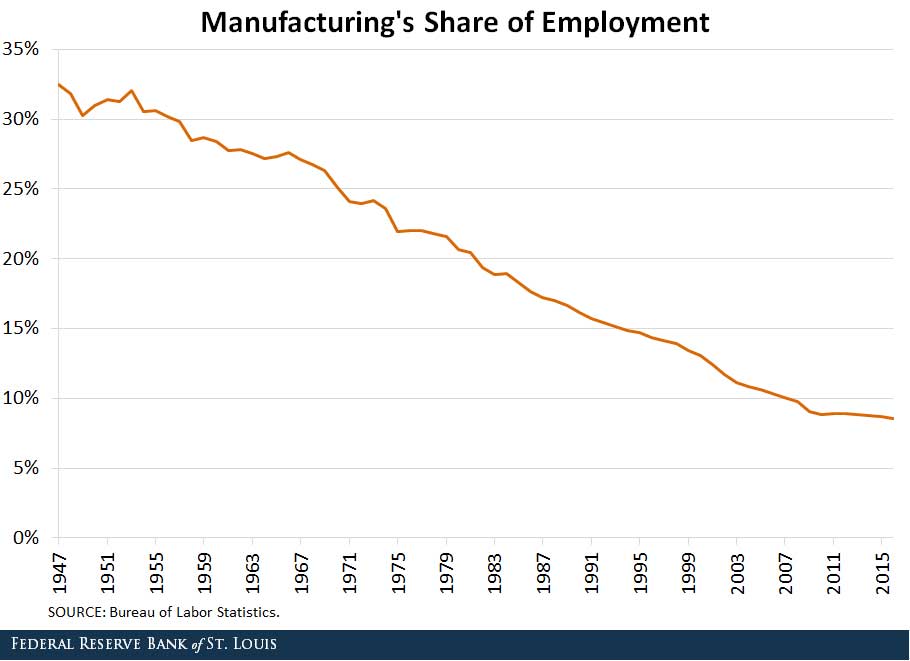

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. The basic idea behind Six Sigma is to improve quality by improving processes through standardization and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If it is too large, it means that there are problems.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have this understanding, you will need to identify sources and causes of variation. You'll also want to determine whether these variations are random or systematic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

After identifying the problem areas, you will need to devise solutions. That solution might involve changing the way you do things or redesigning the process altogether. You should then test the changes again after they have been implemented. If they don't work, you will need to go back to the drawing boards and create a new plan.