No matter what level of education you hold, there are many highly-paid careers that you could pursue in mathematics. Mathematicians have a high demand worldwide. Mathematicians are able to find work in both the public and private sectors. They use math to solve real-world problems. Mathematicians have played an important role in many engineering and scientific breakthroughs, including the Human Genome Project. Mathematicians use mathematics theory, algorithms and computational techniques in solving problems. For their work, they use the latest computer technology. Mathematicians have the ability to send secure emails, shop online securely, and solve complex problems.

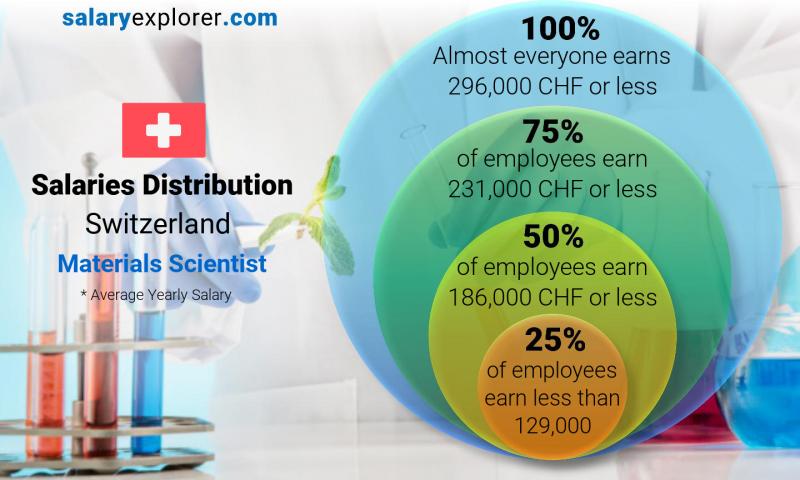

A mathematician's salary is usually higher than the average salary. These salaries are typically very generous and allow for a comfortable lifestyle. A graduate degree is an option for mathematicians to enhance their earnings. The average salary for a mathematician is $103,000 annually. This range may vary depending on where you live or the industry that you work in.

The specialty of applied mathematics is math that emphasizes using math in science, engineering and business. Applied mathematicians combine mathematics theory with specialized knowledge in order to solve specific problems. Mathematicians may work in many different fields such as finance, ecology, engineering, and finance. Applied mathematicians may also be employed in long-term and healthcare care.

The salary of a mathematician can be very high, especially in federal government. Mathematicians in this area work with data and are vital to the allocation of resources for some of the largest military forces in the world. There are many databases that give insight into different sectors. This information can be used to allocate resources for military and federal budgets as well as other large programs. Mathematics graduates with a bachelor's degree can apply for entry-level jobs in the private or public sectors. Specialized training is necessary for government careers.

Applied mathematicians will also be needed in the banking, finance, and insurance industries. This specialty allows mathematicians to work in areas such as digital imaging, ecology, economics, and more. Mathematicians can analyze the aerodynamic characteristics, as well as the effectiveness of drugs. They also provide information about liability insurance and insurance for property.

Applied mathematicians might also be employed in hospitals and insurance companies. Because they can provide information on large programs, mathematicians are essential for the government. Mathematicians with a master's degree in math can find employment in a variety of industries, including finance, actuarial science, and computer science. Mathematicians can also work in research fields as they are skilled at using data and algorithms, solving complex problems.

Numerous math majors are interested in careers in finance and business because they have the option to take a variety of finance classes. This could lead to a career as a financial advisor, actuary, or budget analyst. You can also apply for jobs in cybersecurity, cryptography, or military counterintelligence. A master's level in mathematics can lead you to a career working in computer development. A master's in mathematics will result in a 38% salary increase over a bachelor's.

FAQ

What is the job of a manufacturer manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should also be aware and responsive to any company problems.

They should also know how to communicate with other departments such as sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

Is it possible to automate certain parts of manufacturing

Yes! Automation has been around since ancient times. The Egyptians discovered the wheel thousands and years ago. Today, robots assist in the assembly of lines.

Robotics is used in many manufacturing processes today. They include:

-

Robots for assembly line

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation could also be used to improve manufacturing. 3D printing, for example, allows us to create custom products without waiting for them to be made.

What is the difference between a production planner and a project manager?

A production planner is more involved in the planning phase of the project than a project manger.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing refers to a set of principles that improve the quality, speed and costs of products and services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing can be found in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five principles are the basis of lean manufacturing:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses have adopted lean production techniques to make them more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. It is better to repair a part than have it removed from the production line if it needs to be fixed. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement refers to continuous improvement of processes as well people and tools.